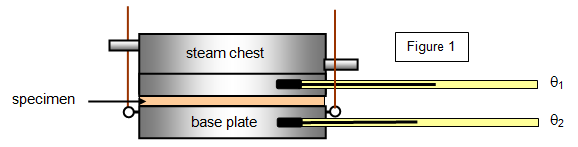

With a poor conductor the rate of flow of heat will be small and so a thin specimen with a large cross-sectional area has to be used. The apparatus is known as Lee's disc, and is shown in Figure 1.

The specimen rests on a brass base plate and a steam chest is placed on top. Steam is passed through the chest and the temperature of the base plate and the base of the steam chest is measured.

The

thermometers are set in good thermal conductors and therefore the temperatures that they

measure are effectively those of the faces of the specimen. Vaseline may be placed in the holes

to ensure even better contact.

When a steady state has been reached the temperatures

q1 and q2 are recorded. The rate of loss of heat from the baseplate

being by radiation and convection, the baseplate is polished so that radiation losses are small

and Newton's law of cooling can be applied. We can assume that the heat lost from the sides of

the specimen itself is negligible.

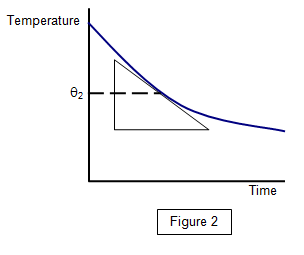

The

rate of loss of heat from the base plate can be found as follows. The specimen is removed and

the base plate heated directly by the steam chest to nearly 100 oC. The steam chest

is then removed, the specimen replaced and a cooling curve plotted for the base plate and

specimen (Figure 2). The rate of cooling R at the temperature q2 can be found by taking the gradient of the curve at that

point, and if the mass m and specific heat capacity (c) of the material of the base plate are

known, its rate of loss of heat can be found.

The thickness L and cross-sectional area A

of the specimen can be found using vernier calipers.